|

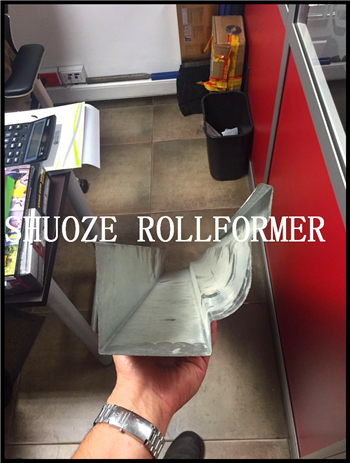

Botou Shuoze Machinery Manufacturing co.,ltdProfessional Rollformer manufacturer to US And Europe market |

|

||||||

2, Falling water roll former detailed parameters:

|

Performances |

Parameters |

|

Suitable material |

Galvanized coil |

|

Material size and thickness |

Thickness:0.43-1.1mm |

|

Productivity |

8-12m/min |

|

Roller forming steps |

20 steps forming rollers |

|

Roller material |

No.45# steel after quenching and with chromium. |

|

Diameter of active shaft |

Φ70mm |

|

Main machine structure |

400H |

|

Wall plate |

20mm |

|

Power |

Two 7.5KW main motor,cycloidal reducer work stable and no noise |

|

Shear |

Hydraulic shear, cutting automatically, blade material CR12, Blade will not damage the profile, before machine leave factory, we test the machine and rolling the panel many times. |

|

Transmission |

1.2’’ chain hanging inside of main structure |

|

Control system |

Delta PLC computer control system with Delta inverter to ensure precision; Winwen color touch screen. Program is made by English. working mode: automatic and manual . We insert the program into the PLC already . We will test machine with the Control system here before machine leave factory. |

|

Hydraulic system |

4kw hydraulic motor and large oil pump |

|

Voltage |

440V/3 phase/60hz |

|

Set off table |

Two pcs, 5 step roller and adjustable screw, each is 3000mm long |

|

Size(length*width*height) |

9500*800*1500MM |

|

Weight |

4500kgs |

|

Component |

Upgrade manual decoiler-forming part-shear blade device--hydraulic system-PLC computer control cabinet-set off table |

3. Falling water roll former components:

|

Machine components |

|||

|

No. |

Name |

Note |

Set |

|

1 |

Decoiler |

Manual (Hydraulic decoiler with carriage for optional) Loading weight: 5 -10 Ton Max suitable coil width:1250mm |

1 |

|

2 |

Feeding device |

To guide coil into machine |

1 |

|

3 |

Main roll forming |

13 steps to form the desired profile |

1 |

|

4 |

Hydraulic cut |

Cut the desired length automatically |

1 |

|

5 |

Hydraulic system |

Provide power to cutting |

1 |

|

6 |

PLC control box |

All program is setted in it and it control the whole machine working automatically |

1 |

|

7 |

Set off table |

Get the formed panel which come out of the machine |

6 meters |

|

8 |

Machine legs |

Added on machine to increase machine height for tall workers |

4 |