|

Botou Shuoze Machinery Manufacturing co.,ltdProfessional Rollformer manufacturer to US And Europe market |

|

||||||

Highway Barie Roll Forming Machine

Product Description:

Highway Barie Roll Forming Machine

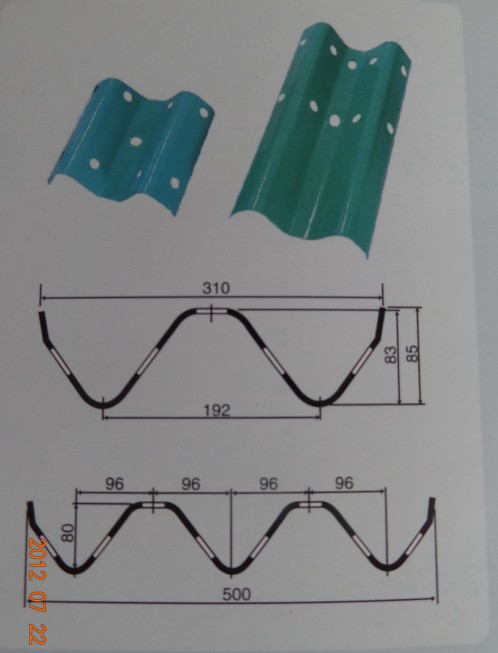

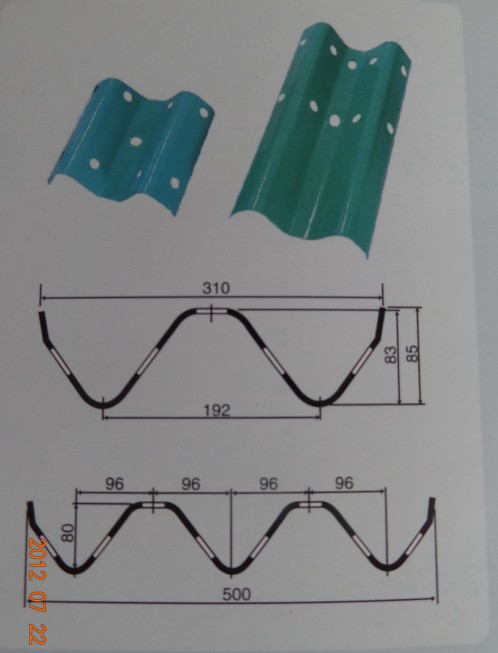

1. profile and size.

There are two waves and three waves.

2. highway barie machine parameters

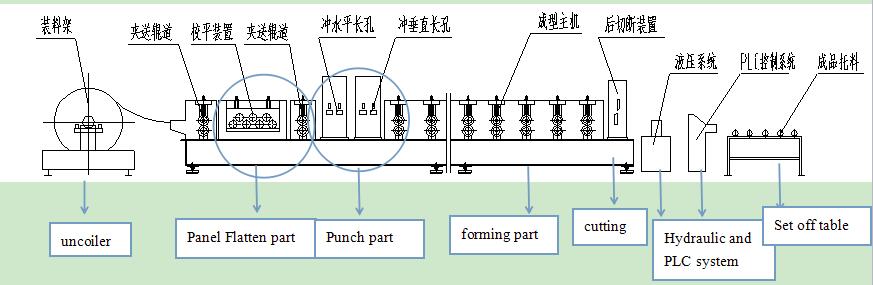

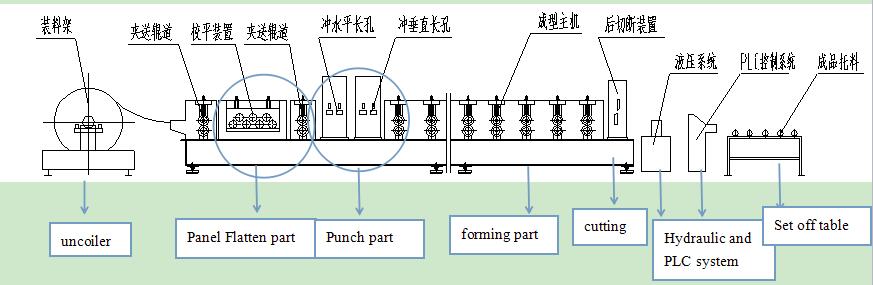

3. work flow

There are two waves and three waves.

2. highway barie machine parameters

|

Performances

|

Parameters

|

|

|

Suitable material

|

Q235 or as your need

|

|

|

Material size and thickness

|

Material width:480mm or as your need

Thickness:3mm

|

|

|

Productivity

|

10-15m/min

|

|

|

Roller forming steps

|

15 steps

|

|

|

Roller material

|

Gcr15bearing steel after heating treatment, HRC58-62

|

|

|

Diameter of active shaft

|

Φ95mm

|

|

|

Shaft material

|

45# steel

|

|

|

Main structure

|

400H welded

|

|

|

Main forming Power

|

37KW

|

|

|

Flatten part motor

|

5.5KW

|

|

|

Shear

|

Hydraulic shear, blade material CR12

|

|

|

Hydraulic part

|

15kw, pressure 20MPA

|

|

|

Transmission

|

||

|

Punch

|

Yes. Hydraulic drived punch

|

|

|

Punch and shear material

|

CR12 quenching treatment HRC58-60

|

|

|

Control system

|

Delta PLC computer control system with Delta inverter to ensure precision; Winwen color touch screen.

Program is made by English, working mode: automatic and manual

|

|

|

Voltage

|

380V/3 phase/50hz or as your need

|

|

|

Set off table

|

Two pcs, 5 step roller and adjustable screw, each one is 3000mm long

|

|

|

Size(length*width*height)

|

13500x2700x1600MM

|

|

|

Weight

|

21,000kgs

|

|

|

Component

|

Upgrade manual decoiler-flattenning part-punching part-forming part-shear blade device--hydraulic system-PLC computer control cabinet-set off table

|

|

3. work flow

Upgrade manual decoiler-flattenning part-punching part-forming part-shear blade device

--hydraulic system-PLC computer control cabinet-set off table

4. Machine components:

--hydraulic system-PLC computer control cabinet-set off table

4. Machine components:

(1) upgrade manual Decoiler

Function: support and develop steel coil.

Weight: ≦ 5T or as your need

⑵ Leveling loading machine

Function: Leveling panel

Structure: leading device, leveling roll (7 rolls), two material directing rollers, and stand.

Alternating current machine driving; gear and chain transmission.

Application and parameter:

Panel width: 550mm max

Thickness: 2.5-3.0mm

Leveling speed: 12m/min

Power: 5.5kw

⑶ Punching machine1# and 2#

Function of punching machine1#: Punching Horizontal

hole

Structure: adopt stable performance and reasonable structure four columns and whole punching mold to make sure precise hole locations.

Application and parameter:

Function of punching machine 2#: punching vertical hole

Structure: adopt stable performance and reasonable structure of four columns and Cr12 quenching treatment of mold material

⑷ Roll forming machine

Adapt Universal joint transmission gear box to ensure good pressure at each step rollers

Rollers steps: 15 material:Gcr15bearing steel after heating treatment, HRC58-62

Shaft diameter: 95mm material:45# steel

Power: 37kw

⑸ Cutting machine

Function: cutting

Structure: adopt stable performance and reasonable structure of hydraulic driving to make sure no scrap.

Application and parameter:

Cutter material: Cr12

Treatment: quenching

Panel thickness: 3mm max

⑹ set off table

Function: Support and output panel.

Structure: stand and supporting roll

Application and parameter:

Two ends and 3m per panel

⑺ Hydraulic system

Function and structure: supply power for punching machine and cutter machine

Pressure:20Mpa

⑻ Control system

Function: control start, revolution and stop of the whole production line.

Structure: Power distribution cabinet, control table and counter.

Adopt PLC control system to set length.

Operation: artificial and automatic

Copyright © Botou Shuoze Machinery Manufacturing co.,ltd All right reserved