|

Botou Shuoze Machinery Manufacturing co.,ltdProfessional Rollformer manufacturer to US And Europe market |

|

||||||

C purlin roll forming machine

Product Description:

C purlin roll forming machine

This machine is designed automatically to change different C size by controlled on PLC eletric box.

So it works with high speed and very popular now.

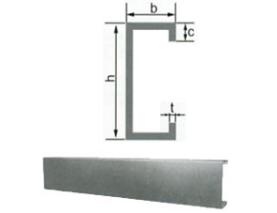

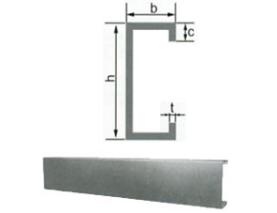

1. C purlin and size

common size is 80-300mm. max thickess is 3mm.

The size can be changed. Our engineer can design machine as your size.

So it works with high speed and very popular now.

1. C purlin and size

common size is 80-300mm. max thickess is 3mm.

The size can be changed. Our engineer can design machine as your size.

|

C Purlin Dimensions Table

|

|||||

|

Model

|

Section Sizes(mm)

|

Hole Distance(mm)

|

|||

|

h

|

b

|

c

|

t

|

||

|

C80

|

80

|

40

|

15

|

2.0-3.0

|

No Hole

|

|

C100

|

100

|

50

|

20

|

2.0-3.0

|

40

|

|

C120

|

120

|

50

|

20

|

2.0-3.0

|

Changable

|

|

C140

|

140

|

50

|

20

|

2.0-3.0

|

Changable

|

|

C160

|

160

|

60

|

20

|

2.0-3.0

|

Changable

|

|

C180

|

180

|

60

|

20

|

2.0-3.0

|

Changable

|

|

C200

|

200

|

60

|

20

|

2.0-3.0

|

Changable

|

|

C220

|

220

|

70

|

20

|

2.0-3.0

|

Changable

|

|

C250

|

250

|

70

|

20

|

2.0-3.0

|

Changable

|

|

C300

|

300

|

80

|

20

|

2.0-3.0

|

Changable

|

2. C purlin roll forming machine parameters.

|

Performances

|

Parameters

|

|

|

Suitable material

|

Galvanized coils or as your need

|

|

|

Material size and thickness

|

Size:80-300mm or as your need.

Thickness:1.5-3mm

|

|

|

Productivity

|

20-25m/min

|

|

|

Roller forming parts

|

Flatterning part: 11 steps (up 5 steps, bottom 6 steps)

Guide shaft and guide wheel

Main forming part: 13 steps

Auxiliary Side rollers: 6 steps

Alignment rollers: 2 steps

Note: show you pics below

|

|

|

Roller material

|

GCT15 bearing steel after quenching and with chromium.

|

|

|

Diameter of main forming active shaft

|

Φ85mm

|

|

|

Diameter of flatterning part shaft

|

Φ100mm

|

|

|

Shaft material

|

45# steel CNC processing and heat treatment to 58-60°

|

|

|

Main machine structure

|

400H

|

|

|

Wall plate

|

30mm

|

|

|

Power

|

22KW hydraulic hose motor,work stable and high speed

Size changement drived motor 0.75KW*4 pcs

|

|

|

Hole punching

|

Hole punching automatically. You can make single hole or double holes.

|

|

|

Shear

|

Hydraulic shear,

cutting automatically and size changed by operate PLC system

blade material CR12,

|

|

|

Transmission

|

2’’ chain

|

|

|

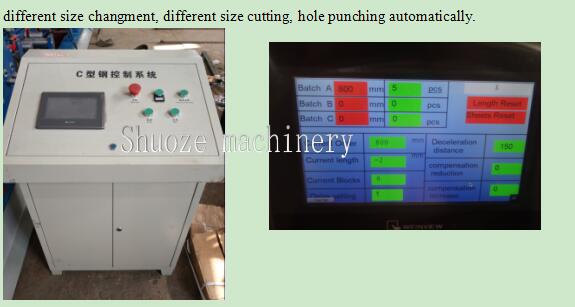

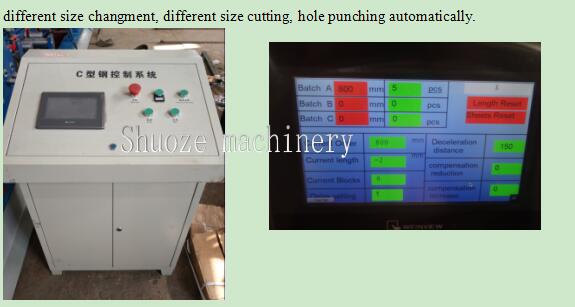

Control system

|

Delta PLC computer control system with Delta inverter to ensure precision;

Winwen color touch screen.

Program is made by English.

working mode: automatic and manual .

We insert the program into the PLC already . We will test machine with the Control system here before machine leave factory.

|

|

First part: main machine forming part

Flatterning shaft and wheel

Auxiliary Side rollers: 6 steps

Main forming steps

Second part: hole making and cutting part

Shear mould do not need to change mould size. It finished on PLC control system with few minites.

Third part: Hydraulic hose motor system

Power 22kW, ensure work stable and high speed

Size changement drived motor 0.75KW*4 pcs

Fourth parts: PLC control system to control machine running ,

Fifth part. Manual decoiler. Loading coil weight 5000kgs

Copyright © Botou Shuoze Machinery Manufacturing co.,ltd All right reserved