|

Botou Shuoze Machinery Manufacturing co.,ltdProfessional Rollformer manufacturer to US And Europe market |

|

||||||

4*9'' AG panel rollformer for Roof

Product Description:

36''(4*9'') AG panel rollformer for US market

1. CE and ISO

2. 15 year experience

3. export to USA market

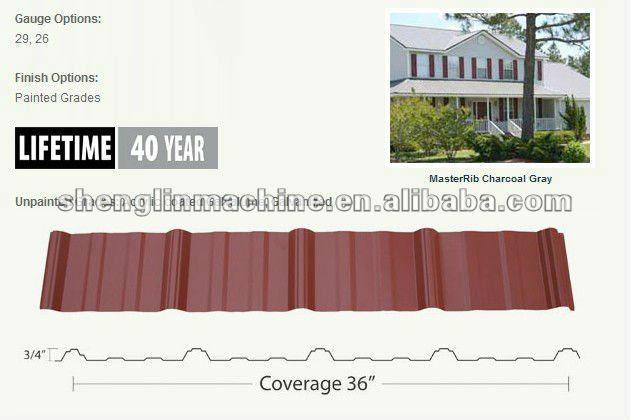

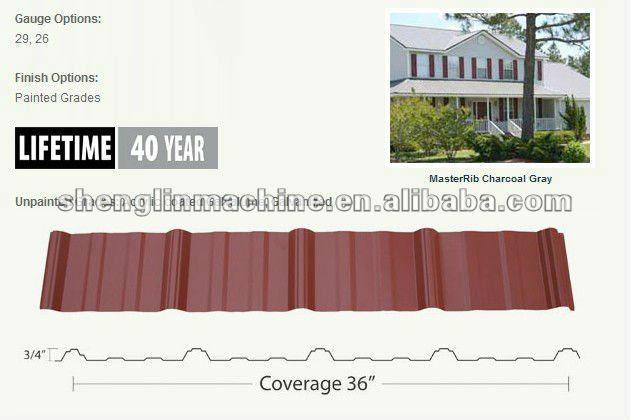

Panel size:

Raw material width: 40.875’’

Material thickness:26-29 guage

Rib height:3/4’’

Rib distance:9’’

Effective panel width:36’’

1. Every year, we sell more than 20 sets ag panel machines to America market. with richful experience, we develop three type design of 11 step roller, 13 step rollers and 17 steps roller machine to meet different buyer need.

2. According to American market need, we make machine rollers, spacers, balance bar and screw do chrome.

You will see details pic below.

If you are tired of those Chinese bad machines, and want to buy high quality machines in

China, Just stop searching!we are your best choice!We offer you quality machine with good price!

A profile with size

E. set off table with 6 step rollers so that it is easy for fork to get panels

B parameters of 36''(4*9'') AG panel rollformer

|

Performances

|

Parameters

|

|

|

Suitable material

|

PPGI or galvanized coil

|

|

|

Suitable material

|

Raw material width:40.875''

thickness 26-29guage or 0.0142''

|

|

|

Productivity

|

12-15m/min

|

|

|

Roller forming steps

|

13 step synchronous forming /17 steps forming like christmas tree

|

|

|

Roller material

|

45# after heating treatment and with chromium

|

|

|

Spacer, balance bar, screw

|

All do chromium to ensure beautiful appearance

|

|

|

Diameter of active shaft

|

Φ70mm

|

|

|

Main machine structure

|

350H

|

|

|

Wall plate

|

16mm

|

|

|

Power

|

5.5KW main motor,cycloidal reducer work stable and no noise

|

|

|

Shear

|

Hydraulic shear, blade material CR12

|

|

|

Transmission

|

1’’ gear chain

|

|

|

Control system

|

Delta PLC computer control system with Chrizi inverter to ensure precision; Winwen color touch screen.

Program is made by English, working mode: automatic and manual

|

|

|

Hydraulic system

|

4kw hydraulic motor

|

|

|

Voltage

|

AC380V/50HZ/3 phase

|

|

|

Upgrade manual decoiler

|

Max loading weight:5000kgs,Inner Diameter:508-610mm,max coil width:1250mm

|

|

|

Set off table

|

one pcs, 6 step roller, each is 3000mm long

|

|

|

Size(length*width*height)

|

8000*1500*1500MM

|

|

|

Weight

|

6500kgs

|

|

|

Component

|

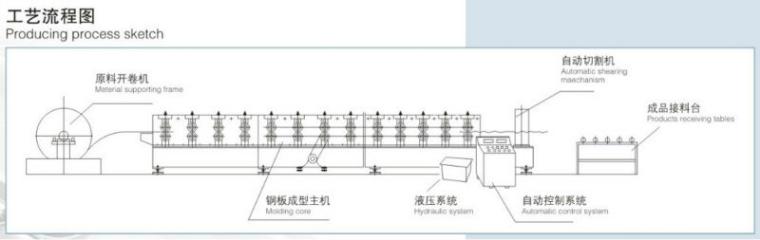

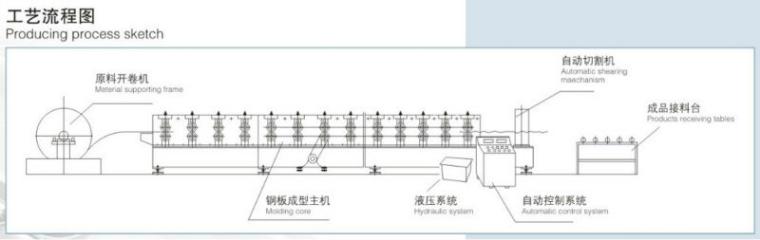

Upgrade manual decoiler-guide feeding-forming part-shear blade device--hydraulic system-PLC computer control cabinet-set off table

|

|

C flow chart of AG panel rollformer

D machine components

|

Machine components

|

|||

|

No.

|

Name

|

Note

|

Set

|

|

1

|

Decoiler

|

Manual (Hydraulic decoiler with carriage for optional)

Loading weight: 5 -10 Ton

Max suitable coil width:1250mm

|

1

|

|

2

|

Feeding device

|

To guide coil into machine

|

1

|

|

3

|

Main roll forming

|

13 steps to form the desired profile

|

1

|

|

4

|

Hydraulic cut

|

Cut the desired length automatically

|

1

|

|

5

|

Hydraulic system

|

Provide power to cutting

|

1

|

|

6

|

PLC control box

|

All program is setted in it and it control the whole machine working automatically

|

1

|

|

7

|

Set off table

|

Get the formed panel which come out of the machine

|

6 meters

|

|

8

|

Machine legs

|

Added on machine to increase machine height for tall workers

|

4

|

F. Spare parts we bring for you free

1.button, two 2. switch, one 3. relay, one 4. Travel switch: two

5. Contactor: one 6. machine paint: one small box

7. Encoder:one 8. Machine install and operation manual: one

If you are tired of those Chinese bad machines, and want to buy high quality machines in

China, Just stop searching!we are your best choice!We offer you quality machine with good price!

Copyright © Botou Shuoze Machinery Manufacturing co.,ltd All right reserved